Ronacrete Ronafix SBR (for Concrete Repairs) Mortars

RONAFIX SBR (FOR CONCRETE REPAIRS) MORTARS

RONAFIX SBR (FOR CONCRETE REPAIRS) MORTARS

Ronafix SBR is a single part modified styrene butadiene liquid additive for cement mortars which enhances physical and chemical properties, allows mortars to be placed in thin section, provides waterproofing and resistance to frost and promotes adhesion to building surfaces.

INFORMATION

BRAND

Ronacrete

PRODUCT TYPE

Mortars

RONAFIX SBR

- Mix A : 9 litres

- Mix D : 12 litres

COLLECTION

Ronafix

PRODUCTION

Made in United Kingdom

PACKAGING

Ronafix SBR is supplied in 5 litre, 25 litre, 210 litre and 1000 litre containers.

YIELD

Mix A & Mix D : 0.1m3

MATERIAL

Cement & Concrete

TENSILE STRENGTH

- 7 days : 5.0N/mm2 (5.7N/mm2)

- 28 days : 7.1N/mm2 (8.4N/mm2)

FLEXURAL STRENGTH

- 7 days : 12.9N/mm2 (15.8N/mm2)

- 28 days : 16.2N/mm2 (19.1N/mm2)

COMPRESSION TESTS

100mm cubes

FLEXURAL TESTS

100 x 25mm x 25mm prisms

MIX DESIGNS & PHYSICAL PROPERTIES

There are 2 mix designs when using Ronafix SBR as a concrete repair mortar. Ronafix SBR Mix Design A is used for concrete repairs where there is no exposed steel reinforcement and Ronafix SBR Mix Design D is used where any reinforcement is exposed.

SHELF LIFE AND STORAGE

Ronafix SBR should be stored unopened between 5°C and 25°C in dry warehouse conditions away from direct heat and sunlight. Shelf life is approximately 9 months in unopened containers.

PERFORMANCE

Mortars containing Ronafix SBR are used for a wide range of applications where thin high strength high performance mortars are required. Typical minimum application depth is 6mm.

COMPRESSIVE STRENGTH

- 1 day : 38N/mm2 (22N/mm2)

- 7 days : 56N/mm2 (42N/mm2)

- 28 days : 70N/mm2 (53N/mm2)

FEATURES AND BENEFITS

- Frostproof

- High tensile strength

- High flexural strength

- Application from 6mm

- High compressive strength

- Provides protection to steel reinforcement from carbonation

- Repairs incorporating Ronafix will have at least the life of the surrounding concrete

TENSILE TESTS

Dumbell Specimens

CEMENT (CEM II 42.5)

Mix A & Mix D : 50kg

MEDIUM SHARP SAND

Mix A & Mix D : 125kg

INSTRUCTIONS FOR USE

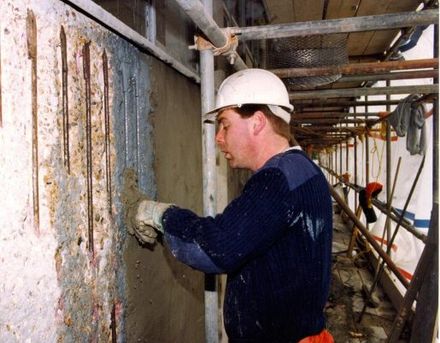

PRIMING

-Brush apply a 1:1 Ronafix SBR:cement primer coat to the steel and allow to become tacky, not dry. If the primer dries it must be thoroughly scarified and reapplied. -When priming coat on steel is tacky, brush a single coat of primer on to the damp concrete or substrate and apply a second coat on to the steel. Ensure that the first priming coat applied to the steel is not removed during the application of the second coat. -The Ronafix SBR repair mortar must be applied on to the wet or tacky primer before the primer dries. If the primer dries it must be thoroughly scarified and reapplied.

DAMPING

Following preparation of concrete and steel, thoroughly damp all concrete surfaces to be repaired. Remove any standing water. Water used must be clean and of potable quality.

PLACING

-Apply the mortar in layers to achieve the required thickness, reform the original profile of the concrete and cover reinforcing steel. Layer thickness will vary according to the nature of the substrate, the shape and size of area being repaired and mixing and application technique. -Materials may be applied using a combination of hand packing or traditional tools. The concrete repair mortar must be well compacted to prevent honeycombing and voids.

-Apply the concrete repair mortar in successive layers to achieve the required thickness. Scratch the face of intermediate layers and apply a coat of Ronafix SBR:cement primer immediately prior to applying the next layer. -If applying a protective or decorative coating leave the final layer with a sponged or wood float finish to aid adhesion. -Cure the finished repair with Ronacrete Curing Membrane or tight fitting polythene.

MIXING

-Mix the Ronafix SBR modified mortar and apply in layers to achieve the required thickness, reform the original profile of the concrete and cover reinforcing steel. Layer thickness will vary according to the nature of the substrate, the shape and size of area being repaired and mixing and application technique. -Ronafix SBR modified mortars can be mixed by hand or machine. Machine mixing will more easily provide a mortar with even dispersion of mix components and a lower water/cement ratio. The use of a forced action mixer (eg. Creteangle or drill and paddle) will provide optimum performance; free fall mixers cause the mortar to ball up with a resultant reduction in performance and must not be used.

PREPARATION

-All concrete and defective material identified for removal must be removed back to a suitable substrate which is sound and stable and which will accept the repair mortar. -Reinforcing steel in the repair area must be exposed, and concrete cut back along the length of the steel to expose not less than 25mm of clean uncorroded steel. Loose rust and scale must be removed (eg. by the use of wire brushing and/or emery cloth or sand paper). Cut around the periphery of spalled areas to a minimum depth of 6mm at 90o to avoid dished edges and feather edged repairs.

-The concrete must be removed around the steel to allow not less than 15mm of repair mortar to be placed around the steel. Corroded steel must be replaced where considered necessary by the engineer. -All removal of concrete and steel must be carried out in accordance with the specifiers recommendations. -All surfaces must be cleaned to remove loose dust, debris and surface contamination which may prevent adhesion of repair mortar to concrete and steel. -When repairing chloride contaminated concrete steel must be grit blasted back to bright steel.