Ronacrete RonaDeck Ultra Bound Aggregates

RONADECK ULTRA BOUND AGGREGATES

RONADECK ULTRA BOUND AGGREGATES

UV stable resin bound system suitable for use worldwide

RonaDeck Ultra Bound is a two component polyurethane resin which binds kiln-dried aggregates to produce a UV stable, SUDS compliant permeable surface.

INFORMATION

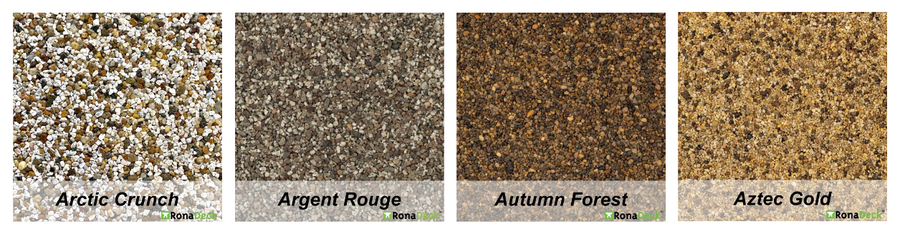

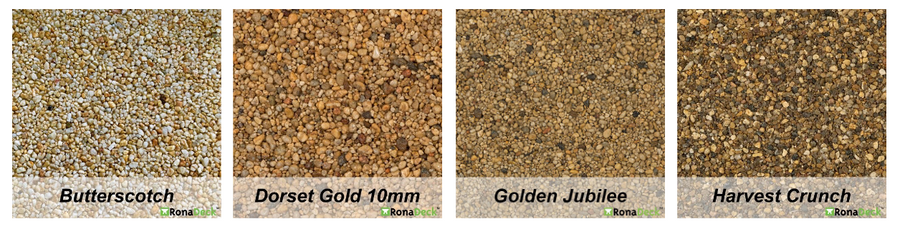

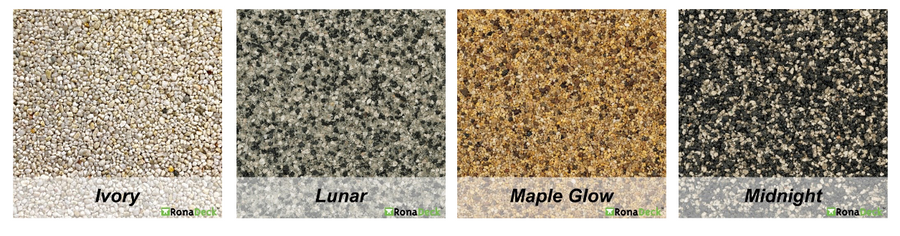

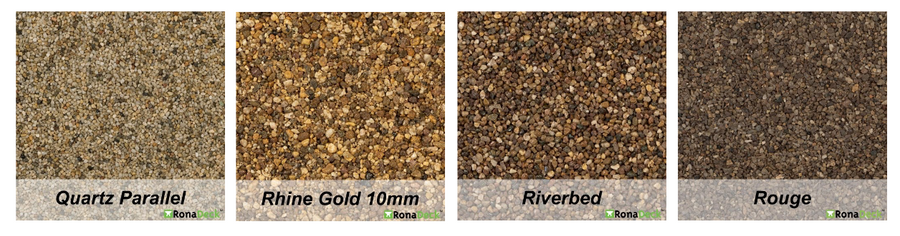

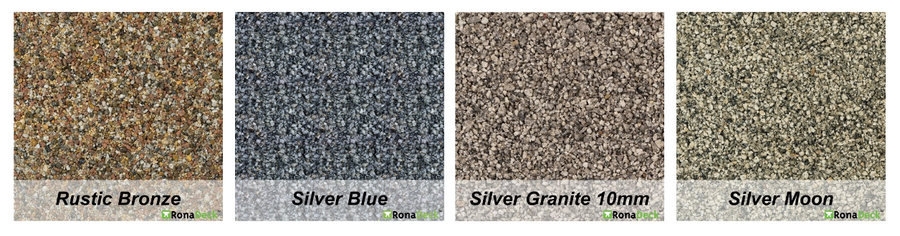

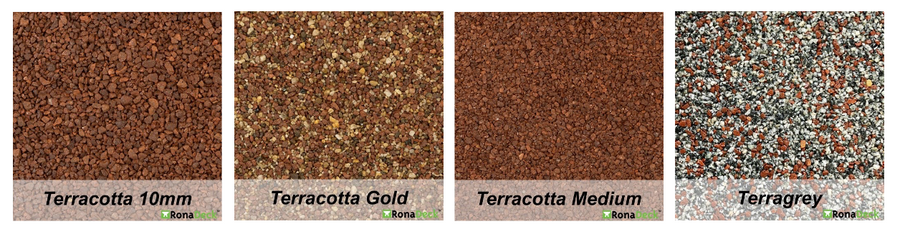

AGGREGATE TYPES

Only mix with suitable washed and kiln dried aggregates

BRAND

Ronacrete

PRODUCT TYPE

Aggregate

COLLECTION

RonaDeck

DELTA E VALUE

<1

SURFACE

RonaDeck Ultra Bound provides an attractive porous surface which is strong enough for foot and light vehicle traffic. RonaDeck Ultra Bound is designed for use on pathways, patios, driveways, pool surrounds. Whilst RonaDeck Ultra Bound is supplied pre-catalysed, additional catalyst may be added on site. A guide on adding catalyst can be provided.

FEATURES AND BENEFITS

- Low VOC

- Slip resistant

- Low maintenance

- SuDS compliant

- Natural appearance

- Will not discolour or degreade

- UV stable anywhere in the world

APPLICATION THICKNESS

When mixed with kiln dried aggregates no larger than 6mm in diameter, the minimum application thickness is 15mm for foot traffic and 18mm for driveways.

ENVIRONMENTAL IMPACT

-The cured system is considered non- hazardous. -The material is manufactured in a BS EN ISO 14001:2015 accredited facility

APPLICATION CONDITIONS

-Temperatures must be at least 5°C on a rising thermometer. -Application during rain or when rain is anticipated during the cure period is not recommended.

MATERIAL

Resin & Polyurethane

PRODUCTION

Made in United Kingdom

PERFORMANCE UNDER UV LIGHT

Standard pu formulations achieve delta e values in excess of 30 whereas ronadeck ultra bound achieves a value of 0.99. Delta e values of 2 and below are not considered to be visible to the human eye. Uv degradation of standard pu formulations will reduce the physical properties, in particular the elasticity, toughness and the impact resistance of the surface. Properties of ronadeck ultra bound are unaffected by exposure to uv light.

SUITABLE FOR

- Pathways

- Driveways

- Car Parks

- Pool Surrounds

TESTING

Tests carried in accordance with BS EN ISO 527-1:2019 and samples prepared in accordance with BS EN ISO 527-2:2012.

SHELF LIFE AND STORAGE

Shelf life of RonaDeck Ultra Bound is 6 months. Store materials in clean, dry, frost free warehouse conditions between 5°C and 25°C. Protect from sunlight.

TECHNICAL DATA

POLYURETHANE BINDER - 2 PART

QUV/se Method: ASTM G154 Cycle 1 (1000 hours). Tests carried in accordance with BS EN ISO 527-1:2019 and samples prepared in accordance with BS EN ISO 527-2:2012.

| PROPERTIES | INITIAL RESULTS | AFTER 1000 HOURS IN QUV/SE* |

|---|---|---|

| Tensile Strength (N/mm2) | 7.19 (7 days) | 10.78 |

| E-modulus (N/mm2) | 27.92 (7 days) | 53.87 |

| Toughness (MJ/m3) | 3.93 (7 days) | 6.47 |

| Elongation (%) | 91 (7 days) | 88 |

| Shore D Hardness | 43 (14 days) | 43 |

DELTA E VALUES - RONADECK ULTRA BOUND VS STANDARD PU

QUV/se Method: ASTM G154 Cycle 1 (1000 hours).

| PROPERTIES | RONADECK ULTRA BOUND | RONADECK ULTRA BOUND | STANDARD PU | STANDARD PU |

|---|---|---|---|---|

| Colour Co-ordinate | Initial | After 1000 hours | Initial | After 1000 hours |

| L* | 92.86 | 93.02 | 93.72 | 88.02 |

| A* | 0.41 | 0.55 | 0.34 | 0.38 |

| B* | 1.63 | 2.66 | 3.52 | 36.86 |

| ΔE | - | 0.99 | - | 33.83 |