Ronacrete RonaDeck EcoPath UV Aggregate

RONADECK ECOPATH UV AGGREGATE

RONADECK ECOPATH UV AGGREGATE

RonaDeck EcoPath UV is a resin bound aggregate surface for pedestrian traffic. RonaDeck EcoPath UV surfaces are decorative and functional, seamless and slightly flexible.

INFORMATION

BRAND

Ronacrete

PRODUCT TYPE

Aggregate

TRAFFIC

Foot Traffic After(14-15 hours @ 20°C)

DRAINS

The open matrix allows water to drain through to the base, eliminating water ponding and allowing water to drain to planted areas or land drains. The system is designed to be SuDS compliant reducing the impact of development on flood risk and allowing water to flow into water courses.

COLLECTION

RonaDesk

ENVIRONMENT

Outdoor

APPEARANCE

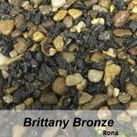

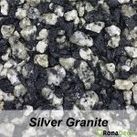

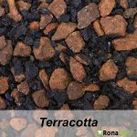

The appearance of samples and of materials supplied by Ronacrete are based on the colour, shade and grading of individual aggregates supplied to Ronacrete by its suppliers. Being largely natural aggregates, the appearance will vary from bag to bag and batch to batch, a uniform appearance should not be expected and cannot be achieved.

PRODUCTION

Made in United Kingdom

AVAILABLE COLORS

Four

FEATURES

- Flexible

- Low maintenance

- Highly decorative

- Available in a range of finishes

- SuDS compliant—highly permeable

- Incorporates recycled rubber from discarded truck tyres

- Installed from 35mm on to compacted MOT Type 1 or Type 3

- UV stable - will not discolour or degrade upon exposure to UV light

AGGREGATE

Some aggregates can contain small amounts of iron which can produce rust staining. This naturally occurring iron cannot be identified before use and Ronacrete cannot accept any responsibility for any loss or damage suffered as a result of staining.

DETAIL

RAIN DURING APPLICATION

Application during rain or when rain is anticipated during the cure period is not recommended. Light rain on the surface of the system is unlikely to affect the surface but may affect the bond between particles, reducing the strength of the system. Note that application to a damp substrate will reduce bond strength. Unmixed aggregate must be kept dry at all times.

SHELF LIFE AND STORAGE

Shelf life of RonaDeck EcoPath UV is 6 months, aggregates have an unlimited shelf life. Store materials in clean, dry, frost free warehouse conditions between 5oC and 25oC. Protect from sunlight.

CONTRACTORS

RonaDeck EcoPath UV is a specialist product and must only be applied by specialist applicators. Do not apply or allow it to be applied by contractors who do not possess the necessary skills and experience. You should consider appointing a Ronacrete Approved Contractor.

MAINTENANCE

It is possible to repair localised damage by cutting out and replacing, ideally using the same aggregate as originally supplied. Ageing and weathering of the original may prevent an invisible repair. “Picking out” of some stones is possible but is likely to be minimal and localised. Any major loss of stone should be reported.

SLIP RESISTANCE

Application of RonaDeck EcoPath UV Anti-Slip Aggregate will significantly increase the slip resistance of the surface in the wet, without substantial change to appearance and its use may help comply with Health and Safety obligations.

SITE ATTENDANCE

When on site Ronacrete representatives are able, if asked, to give a general indication of the correct method of installing a Ronacrete product. It is important to bear in mind that Ronacrete Ltd is a manufacturer and not an application contractor and it is therefore the responsibility of the contractor and his employer to ensure he is aware of and implements the correct practices and procedures to ensure the correct installation of the product and that liability for its correct installation lies with the contractor and not with Ronacrete Ltd.

SUGGESTED CONSTRUCTION SUDS COMPLIANT PERMEABLE CONSTRUCTION FOR FOOTPATHS :

RonaDeck EcoPath UV System is designed for light foot traffic only, a suggested form of paving construction follows

-EcoPath UV Surfacing : 35mm minimum depth of RonaDeck EcoPath UV vulcanised rubber granules and natural aggregate bound with RonaDeck EcoPath UV Resin. -Granular Sub-base : 175mm minimum well compacted Type 3 granular sub-base or similar approved. -Optional Impermeable Membrane : Impermeable membrane to carry water to infiltration/ storage system/ soakawa. -Geotextile Layer : Geotextile layer to prevent upward migration of soi. -Capping Layer : If required, depending on sub-grade condition. -Sub-grade : The above information is produced for guidance only, the designer/ contractor should be satisfied that the construction is suitable for the expected traffic and ground conditions.

MIX DESIGN

- RonaDeck EcoPath UV Resin : 1 x 7kg

- RonaDeck EcoPath UV Aggregate : 3 x 25kg

- RonaDeck EcoPath UV Rubber Granules : 1 x 15kg

- RonaDeck Recycled Fine Aggregate : 1 x 5kg

- Coverage @ 35mm : 2.4m² (approx)

Coverage is based on application to a smooth flat surface and will vary when applied to undulating surfaces, according to compaction, and to the aggregate grading, which can change from batch to batch.

WORKING TEMPERATURES

-Working time is affected by temperature including material, air and substrate temperature. At temperatures above 25°C the pot life and working time may be insufficient to allow its proper application. -Work should therefore not proceed when product, air or substrate temperature exceed 25°C. The temperature of the substrate must therefore be measured and monitored during application and work should stop when temperature is above 25°C. -At low temperatures RonaDeck EcoPath UV Resin will not flow sufficiently to achieve a smooth finish and work should not proceed when air, material or substrate temperature is below 5oC. The surface must not be trafficked until it has gained sufficient strength.

INSTRUCTIONS FOR USE

-Place 90kg RonaDeck Eco Path UV rubber granules and kiln-dried aggregate into a clean, forced action mixer, minimum pan capacity 120 litres, Baron M200 mixer or similar. -Scrape all of the contents of RonaDeck EcoPath UV Resin Part B component into the larger Part A container and mix with a slow speed drill (≤ 450RPM) and MR2 paddle mixer attachment for 2 minutes. Overmixing will increase heat generation and reduce working time. -Immediately add the mixed resin to the aggregate in the mixer. Mix the aggregate and resin together until ll the aggregate is evenly coated with resin. Mix for approximately 3-4 minutes. Overmixing will increase heat generation and reduce working time.

-Discharge the mixed resin and aggregate onto the prepared sub-base, level and smooth. Excessive compaction will reduce permeability. -Finish the surface with a suitable float. RonaDeck Low VOC Tool Cleaner/ Trowel Finishing Aid should be used if required, the use of white spirit is not acceptable. -If required, immediately cast RonaDeck EcoPath UV Anti-Slip Aggregate onto the surface of the wet resin, at the rate of approximately 0.1kg/m2. Ensure even coverage to prevent a patchy appearance. -Allow to cure. At 20oC protect against damage by heavy rain for 12 hours and open to traffic after approximately 14 hours at 20°C