Coveringsetc Eco-Terr® Slabs

ECO-TERR® SLABS

ECO-TERR® SLABS

Environmental - high quality - top design

Eco-Terr® is an environmentally friendly, high-quality terrazzo product that combines aesthetic and mechanical characteristics.

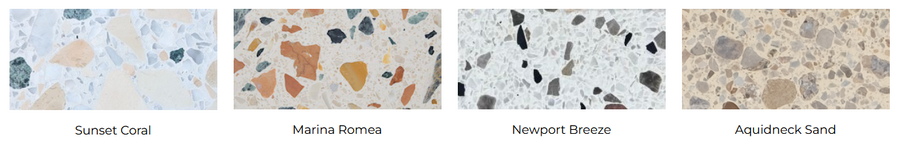

Our Future-Friendly™ terrazzo collection of tiles and slabs come in several styles, finishes and colors with aggregates that range from micro to large formats. Use it on benches, counters, walls and other surfaces for a high-quality finish with stunning design.

INFORMATION

APPLICATIONS

- Interior and Exterior

- Commercial and Residential

- Flooring, Walls, Countertops, Exterior Façade, Pool Terraces, Industrial Design

COLLECTION

Eco-Terr®

PRODUCTION

Made in USA

HEAT ISLAND REDUCTION - NONROOF

4.60M%

STANDARD SIZES SLABS

- 100x56x1¼"

- 120x49x1¼"

DETAIL

-Our Eco-Terr® Terrazzo Slabs are made from recycled Portland cement, which is contamination-free, and recycled marble and granite chips from closed quarries. -The manufacturing process is environmentally friendly, without using resins, epoxies, or VOCs. These features make the slabs resistant to non-microbial growth and promote better air quality. -Additionally, the terrazzo has pre-consumer recycled content, which can help with LEED® credits for USGBC project certification. -Eco-Terr® is also certified for Material Health Grade and is stain, frost, chemical, and fire-resistant. The surface is rectified and calibrated for easy installation and maintenance and has a limitless lifecycle.

TOTAL ACCEPTANCE ANGLE

13.71

RESISTANCE TO ABRASION

18.40 cm³/50cm²

SLIPPAGE RESISTANCE AVERAGE

R9-R11 depending on finish

ENVIRONMENT

Indoor

DENSITY

2.37 g/cm³

COMPOSITION

-Contains 70% pre-consumer recycled content (naturally occurring marble and granite aggregates) with a cementitious binder containing 5% pre-consumer recycled content (fly ash). -Eco-terr® contains a high quantity of stone and cement of the best quality (portland 5.25 1 class) and is mixed with a limited amount of water (ratio water/cement 0.28 – 0.32), resulting in a very homogenous, dense and compact structure. With the process of vacuum-packing with vibro-compaction, the tile becomes better looking and more resistant. -Eco-terr® slabs are pre-cast and may be installed using butt joint method for a seamless landscape.

DOWNLOADS

↓ Eco-terr® finishes

↓ Eco-terr® hpd v2.3

↓ Eco-terr® leed overview

↓ Eco-terr® slabs cut sheet

↓ Eco-terr® slabs specifications

↓ Eco-terr® slabs installation

↓ Eco-terr® sustainability sheet

↓ Eco-terr® slabs care and maintenance

↓ Eco-terr® material safety data sheet

FROST RESISTANCE

Resistant

REACTION TO FIRE

Class A-1

FLEXURAL STRENGTH

6.90 Mpa

BENEFITS

- Calibrated

- Zero VOC’s

- Fire Proof – Class A Fire Rated

- Non-Porous Cleanable Finish

- Easy to install and maintain

- 60+ Life Cycle Assessment factor (LCA)

- Composed of completely natural and eco-compatible elements

- Does not support microbial growth or allow moisture to accumulate

- Highly resistant to UV rays, light, compression, and atmospheric agents

- May help contribute toward LEED® credits with USGBC project certification

- Helps to maintain a mold-free environment with improved indoor air quality

TECHNICAL SPECIFICATIONS

| TEST PERFORMED | ASTM | RESULTS |

|---|---|---|

| Static Friction Coefficient | C-1028 | Dry : 0.95 & Wet : 0.92 |

| Modulus Of Rupture | C-120 | Dry : 1,800 psi & Wet : 800 psi |

| Modulus Of Elasticity | C-469 | 1.75x106 psi |

| Shear Strength | D-732 | Dry : 1.200 psi & Wet : 1.170 psi |

| Tensile Strength | D-209 | Dry : 600 psi & Wet : 450 psi |

| Compressive Strength | C-170 | Dry : 3.900 psi & Wet : 3.000 psi |

| Water Vapor Permeance | E-96 | 6.5 perms |

| Thermal Conductivity (K) | C-58 | 1.43 BTU-In/Hr F |

| Flame Spread And Smoke Development Index | E-84 | Flame : 0 index Smoke : 0 index |

CARE AND MAINTENANCE

CARE AND MAINTENANCE

To maintain surface luster, apply standard cleaning methods and use neutral detergents. Avoid cleaning products that contain acid (even when diluted), alkaline detergents, strong solvents and paint strippers. Cleaning can be simply done by wet mopping with a neutral detergent; then rinse thoroughly with clean water and let dry. To restore waxed surface gloss, coat periodically with a solution of the original finish wax diluted with water.

STORAGE

Do not leave materials outdoors since climatic conditions could affect the material causing damage to the surface or finish. ECO-TERR® is to be stored indoors. Once received it is advised to install materials promptly. Do not leave materials in storage for any length of time as moisture and light can alter condition of materials. Long term storage could cause discoloration or fluorescence, especially in lighter colors. Eco-terr® is made of natural re-cycled stone components. The technical data may vary somewhat with each color blend.

PRODUCT INFORMATION

No two tiles are alike. The allure of consistent irregularity is one of the popular characteristics which create the allure of natural beauty by the blend of component materials that comprise ECO-TERR®. It is recommended that tiles be laid side by side prior to installation to assure an even color blend. Glass and mother-of-pearl are elements that differ in structure from the stone chips. Upon occasion one or more can become dislodged from the surface.

This can happen during the polishing process. These fissures can be evened out with suitable natural stone surface fillers. After installation some tiles may appear to lack uniform coloring. This is a natural phenomenon related to the evaporation process. When freshly installed, the humidity absorbed by the tiles from the adhesive can vary in tone from center to edges. It is destined to disappear during the drying process.

INSTALLATION

FOUNDATION (SCREED OR CEMENT PLASTER)

-Prepare the screed or the plaster using cement mortar and wait its ageing until it reaches a residual humidity < 2% (waiting time: about 1 week for each cm of thickness). The screed must be thicker than 5 cm and respect the existing joints. -Before the laying, check the screed and the plaster suitability. These must be: insulated, dry, stable, solid, compression-resistant, sufficiently flat and free from loose material, dust, greases, oils, waxes, paints, detaching agents and any other items which may reduce adhesion. -Correct any irregularity with levelling and auto-levelling products, taking care to verify the perfect planarity of the plane which mustn’t have level differences higher than 2 mm.

POST-LAYING TREATMENT

On dry and clean surface, apply a stain resistant impregnating hydro-repellent protection (such as FILA MP/90) or oil-repellent that doesn’t alter the aesthetic appearance of the tiles (such as FILAFOB). In alternative to the highly-protective treatment, it is possible to apply a coat of floor-finishing wax (such as VENEZIANA produced by FILA company) with a brush, a rag or with a suitable applicator.

-Before a highly-protective treatment (recommended for floors exposed to high risk such as bars, rotisseries, restaurants, and in any place where the tiles may be stain with oil or mechanical oil) check that the floor is perfectly cleaned, in the contrary proceed before in cleaning the tiles with a degreasing detergent (such as FILA PS/87 diluted 1:10 with water).

INITIAL CLEANING

During the laying use the utmost caution, in order to prevent the staining of the tiles. The basic washing must be made avoiding products containing acid, even when diluted. We also advice strongly against the use of alkaline detergents, very strong solvents and paint strippers. Neutral detergents on sale are therefore recommended (such as filacleaner produced by company fila diluted 1:10 with water). Remove dry dirt using a cloth. Wash with a neutral detergent diluted with water. Rinse with plenty of clean water without detergent and leave to dry.

-For the cleaning of floors without a wax-finish, wash with a neutral detergent (such as filacleaner diluted with water); then often rinse the rag in the detergent always making sure it gets squeezed properly. -For the cleaning of floors having a wax-finish, wash with a neutral detergent (don’t use hot water). In order to restore the tile gloss, wash periodically with the finish wax solution you have used at the beginning (veneziana) diluted with water (2 glasses of wax every bucket of water).

USE AND STORAGE

-Never leave the material outdoors since damage to the packaging or acid or lime-scale rain may damage the surface, reduce its shine and cause marks which are difficult to remove. -It is advisable, once in possession of the material, to proceed as soon as possible with the installation of the material to avoid eventual discoloration or fluorescence, especially in the case of light colors. -Before the installation of the material, verify that it is defects-free; in this case please interrupt the installation and communicate it immediately to Coveringsetc.

-Every supplied order includes some more tiles free of charges as reserve material. It is recommended that the customer apply a check on the laid material within the second day in order to replace any possible damaged tile during the laying. -After the installation of the material, some laid panels may present lack of color homogeneity – as for example darker tile center with respect to the edges. This natural phenomenon is related with the natural evaporation process of the humidity absorbed by the tiles from the glue with which it are laid, and it is destined to disappear. -If panels of the same production batch are laid in different periods, they can present lack of color homogeneity caused by an oxidation process of the cement which the tiles contains.

-Glass and mother-of-pearl These elements differ in kind from the stone and for this reason single pieces of glass or mother-of-pearl may come off from the tiles, especially polishing the floor after the installation. In this case, fill eventual holes with suitable fillings for natural stone, on sale. The same can happen with the grains chips, in this case act in the same way indicated for the glass and mother-of-pearl. -Pay greater attention during the installation of tiles bigger than 24x24 inches, because bigger is the dimension of the tiles, higher is the risk of non-homogeneous planarity among them.

LAYING AND FILLING

-Spread the adhesive on the foundation and lay ECO-TERR® on the wet adhesive before it forms the superficial pellicle. In case of high temperatures and ventilation, the open time of the adhesives (indicated in the specifications) can notably change. Before the laying, we suggest you to plunge the tiles in clean water for a few seconds and then drip the excess of water away, in order to guarantee a safer grip between the tile and the foundation. Carefully press in order to get a flawless adhesion and level the tiles with care and precision, to avoid differences in level among the tiles. Any excess adhesive which comes to the surface during laying must be removed immediately with a wet sponge, to prevent damages to the surface.

-The width of the laying joints (grouts) must comply with the European standards (width at least 2 mm, so that the sealant can penetrate to the required depth at all points). In any case, the dimensions of the tiles and the thermal expansion coefficient could determine the choice of joints having a different width, especially for outdoor flooring. Existing expansion joints must coincide with joints in the tiles, and subdivision joints must be provided (for great surface panels of approx. 170 sq ft), always following the suggestion of the person in charge for the laying.

-Laying must be carried out using adhesives specially developed for laying stone and cement agglomerates. As an indication, we can suggest the following adhesives: flex white, h40rapid or h40marmorex (produced by company kerakoll) or other products with equal technical characteristics, to use following the instruction of the supplier company, also in relation to the weather situation. -The filling of joints must be performed while the adhesive is not yet completely hardened, using professional and colored fillers like fugabella (kerakoll) or similar products with color as similar as possible to the color of the tile. The cleaning of the filler must be done within the right time (while still fresh) by using a sponge and clean water.