Plyboo Plyboo Strand Plywood

PLYBOO STRAND PLYWOOD

PLYBOO STRAND PLYWOOD

PlybooStrand® Bamboo Plywood and Veneer

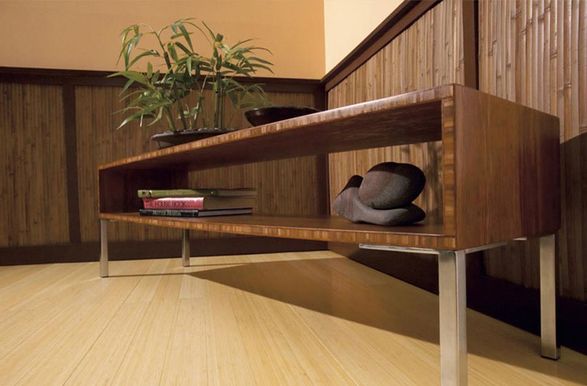

PlybooStrand® bamboo plywood and veneer uses strand technology to turn 100% rapidly renewable bamboo into a beautiful yet exceptionally durable green building material.

INFORMATION

STANDARD SIZES

- 3/4” x 48″ x 96″

- 19mm x 1219mm x 2438mm

- 4mm” x 30″ x 72″ (for edge banding)

- 4mm x 762mm x 1828mm (for edge banding)

USED

Our strand bamboo plywood and veneer sheets are architectural-grade and can be cut and sanded using conventional woodworking equipment. It can be glued and fastened with the same materials used on wood.

DETAIL

PlybooStrand bamboo plywood and veneer is sanded to 180 grit and is available in three colors: Havana, Sahara, and Neopolitan®.

FIRE RATING

Fire resistance classification: Class C Test surface burning in accordance with ASTM E 84

LEED® CREDITS

-MRc6: Rapidly Renewable Materials -ULEF, Ultra Low Emitting Formaldehyde, IEQc4.4: Low-Emitting Materials

WEIGHT

- 3/4” x 48″ x 96″ – 128lbs per

sheet -4mm” x 30″ x 72″ – 15lbs per sheet

WORKING WITH PLYBOO

GENERAL RULES OF USAGE

The three-ply construction, like all cross-ply constructions, are designed for greater stability. The three-ply construction is also the most popular for its versatility of application. Uses for this panel include, cabinetry, shelving, store fixtures, furniture and wall panel systems. If you have further questions about a specific use or application for PlybooStrand bamboo plywood, please feel free to contact our technical support department

CONSTRUCTION OF PLYBOOSTRAND PANELS

The most common is our three-ply construction that has been in use since 1996. This construction employs a perpendicular core running the width of the panel. The core is constructed of multiple strips of standard bamboo material. These strips are laminated into a single-piece core board. The surface plies are assembled of strand face board strips that are approximately 4 1/16” in width and are laminated side-to-side and sanded to dimension, then laminated to top and bottom completing the three-ply construction

CONSTRUCTION OF PLYBOOSTRAND MATERIAL

PlybooStrand material differs from standard Plyboo® material in the processing of the strips and the manufacture of the base material. To explain the full process would be more involved than this document allows, but a basic understanding of the material is still helpful. Strand strips are produced rough and then crushed to open up the material for better adhesive saturation. The strips are submersed in adhesive, dried, and pressed into dense blocks that are then balanced, sliced, and kiln-dried before they are ready for processing. The process to produce the PlybooStrand material from which our panels are made takes approximately 6 weeks to complete

MOISTURE AND HUMIDITY

PlybooStrand panels are manufactured to an average moisture content of 6 to 9%. However, due to environmental conditions, the product you receive may vary. It is recommended that before working a panel that a moisture reading be taken. If acclimation is necessary, this should be performed prior to working the material and should take into consideration the environment and the application at the final installation point. PlybooStrand panels, like wood products, will expand and contract with changes in relative humidity (RH). The greater the seasonal change, the greater the potential for movement

RECEIPT AND PREPARATION

All product should be inspected upon arrival to confirm the condition of the material, that there is no freight damage and that the product conforms to the order. Bamboo will naturally vary in color and this is to be expected. For this reason, all panels to be used should be color paired for best effect. If panels are to be stored prior to working, leave the panels in their protective packaging and stack horizontally.

Prior to fabrication, sheets should be checked for moisture. If the panels need to be acclimated, un-bag and stack horizontally with spacers to allow proper air circulation to occur. Consider the relative humidity (RH) and temperature of the final installation site to establish the appropriate moisture level of the panel prior to working, sealing and finishing.