Elcomsystem Termocoperture Monolithic Panels

TERMOCOPERTURE MONOLITHIC PANELS

TERMOCOPERTURE MONOLITHIC PANELS

The insulating metal panels called TERMOCOPERTURE® are the well-known monolithic panels researched and made by ELCOM SYSTEM S.p.A. (certified UNI EN ISO 9001) to offer the best in the field of light prefabrication.

INFORMATION

TECHNICAL CHARACTERISTICS

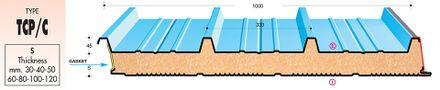

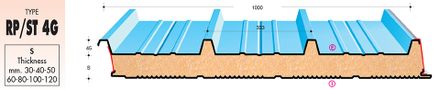

The insulating metal panels called TERMOCOPERTURE® are the well-known monolithic panels researched and made by ELCOM SYSTEM S.p.A. (certified UNI EN ISO 9001) to offer the best in the field of light prefabrication. With the panels TERMOCOPERTURE® it’s possible to realize roofs and ceilings. For tailor made projects the company produces particular joints and special components such as spherical, right and curved connections with thermic cut, to be used to reach a high aesthetic standard.

BRAND

Elcom System

LENGTH OF PANELS

± 5 mm.

INSULATION

Expanded polyurethane (PUR), CFC free, according to UNI EN 13165 norm. On request foams with characteristics of fire-reaction class E, panel class B S3 d0 UNI EN 13501-1. In case of particular needs, foams with a superior fire-reaction (PIR), can be produced, panel class B S2 d0 UNI EN 13501-1.

DENSITY

40 kg/m3~

COMPRESSIVE STRENGHT

140 -150 KPa

PRODUCT TYPE

Panels

PRODUCTION

Made In Italy

CERTIFIED

UNI EN ISO 9001

MATERIALS

The finishing of steel and aluminium supports consists of an organic coat obtained from a cycle of hot standard polyester prepainting, according to EN 10169. On request, different coatings such as PVC alimentary or PVDF can be fournished. It’s possible to manufacture thermocovering panels with bitumized feltpaper and/or centesimal aluminium. Special roof panels for zootechny, called ZOOTEC, are manufactured with the internal support in fibreglass (opaline white). They are indicated for environments with biological exhalations and they are resistant to bacteriums, urea and ammonia.

FLATNESS

-L = 200 mm l ≤ 0,6 mm -L = 400 mm l ≤ 1 mm (L = distance between the points of measurment)

EXTERNAL STEEL SUPPORTS

They are obtained from cold profiling of coils of different material: carbon steel coated with zinc S 250GD according to UNI EN 10326 norms with mechanical characteristics as foreseen in the D.M. of 14.01.2008 and tolerances as UNI EN 10143 norm; aluminium according to UNI EN 1396 norm, with a minimum breaking load of 150 MPa; copper according to UNI EN 1172; and stainless steel according to EN 10088-1 norms; COR-TEN.

OUT OF SQUARE

s ≤0,6% of the useful width

FINISHING

-Steel -Aluminium