Living Concrete Timber Planked Concrete Wall Boards

TIMBER PLANKED CONCRETE WALL BOARDS

TIMBER PLANKED CONCRETE WALL BOARDS

The GRC Timber Planked Concrete Wall Boards are made to look like cast-in-situ timber shuttered concrete. The result is a product which is perfect for wall installation both outdoor and indoor.

Our concrete is manufactured using our bespoke process which allows us to make exceptionally thin panels which have a lot of strength, fantastic UV stability and a superior mechanical resistance. These types of panels can therefore be made in different colours to get the results needed.

The composition of the panels is made from cement along with a special type of sand, carefully chosen additives and stable UV pigments. The result is what you see – a concrete surface which is tough and suitable for many applications. We pre-seal all our panels and offer you a complete installation service for all the products we sell.

Concrete walls are a good choice for any private or commercial space, as they can be tailored to suit your designs and have a longer lifespan than wood or slate. Speak to us today about your specific needs.

INFORMATION

STANDARD SIZES

We offer a selection of standard panel sizes for you to choose from. These panels can also be cut to size to suit any space.

- Minimum order 10m2.

- 2100 × 250 x 12 mm

WEIGHT

18kg/m2/10mm

USE

Internal or external

STORAGE

- Keep in a dry, clean space in the original packaging

- Panels should be kept in a horizontal way

VERIFICATION OF THE AESTHETIC APPEARANCE

Please check and ensure that you are happy with the delivered product and there are no apparent visible defects. If any issues are detected do not start the installation and contact supplier immediately. No claims will be accepted after tiles have been installed.

TOLERANCES

- Thickness +/-5%

- Side straightness : +/-0.5%

- Orthogonality : +/-0.6%

- Planimetry : +/-0.5%

- Length and width : +/-0.6%

BRAND

Living Concrete

CATEGORY

Concrete panels

FINISHES

Unsealed or a choice or Matt, Satin or Gloss (we recommend sealing to limit staining).

GRC CONCRETE FEATURES

-Suitable for floor and wall installation both indoor and outdoor -Large format / ultra thin tiles with superior strength -High mechanical resistance and UV stability -Available in different textures and colours

MECHANICAL PROPERTIES

-Yield strength (modulus of rupture) : 5-8 mpa

-Tensile strength (modulus of rupture) : 2-5 mpa

-Compressive strength : 20-30 mpa

-Impact strength : 5-10 KJ/m2

-Thermal expansion coefficient : 20 x 10-6/°C

-Absorption: Low water permeability

-Dorry wear : 2.5 mm

INSTALLATION

Adhesive or bracket system

DOWNLOADS

↓ Product Sheet

↓ Installation Guide

CLEANING & MAINTENANCE

- Clean with neutral detergent

- Use wax maintainers or self-polishing cleaners

COLOUR VARIATIONS

Because of its cementitious composition the colour of GRC panels may have different textures and tones within the same panel and / or in comparison to other panels in the same batch. Our colour selection chart is for reference use only and the colours are as close as possible to the original colours.

COMPOSITION

- Cement

- Selected sand

- Specially designed additives and UV stable pigments

- The GRC High Performance Concrete panels stand out because of their versatility, durability and high hardness, making them suitable for all types of applications.

INSTALLATION

INSTALLATION GUIDE – WALLS

-Base solid flat surface -There can be no rising or negative humidity -Verify that the base wall is levelled (+/-2 mm in 3 meters) -Allow for the perimeter joints and joints against objects from the base

STORAGE

- Panels should be kept in a horizontal way

- Keep in a dry, clean space in the original packaging

- Do not leave the panels in a vertical or inclined position or leaning against any surface

CONSIDERATIONS BEFORE INSTALLING LC BTX PANELS

- Keep packaged until installation

- Do not force the panels over uneven surfaces

- Always store horizontally

- Do not place loads on the panels

- Level the sub-wall correctly before starting the installation (+/- 2 mm in 3 m)

- BTX panels are not rectified, they can have variations of 0.6%.

(1) DIRECT WALL INSTALLATION WITH ADHESIVE

-Tools And Materials Needed : Spirit Level, Primer, sealer and Polyurethane / Epoxy adhesive, Screws and anchors, Tape measure, Cradle Caulking Gun, Ladder /Scaffold tower/ Access platform, Tile Spacers, Angle grinder, Sandpaper, Paint Tray, Microfibre roller

-Step By Step Manual Installation : The wall should be levelled (+/-2 mm in 3 meters), Sand the wall to remove any loose elements, Apply primer if needed, The base has to be firm. Verify with a sharp tool, Define the way of installation according to the aesthetic wanted, Begin the installation of the panels from the bottom up

-Apply adhesive as per manufacturer’s recommendations -Install panels applying pressure until initial grab -If necessary use T screws on the panels joint to fix them. Once the adhesive is dry remove the screws -Panels joints can be butted, left with shadow gaps or filled with flexible tile grout -Seal the panels with Water Based Sealer, POLIFAN PU K14 or acrylic WAX

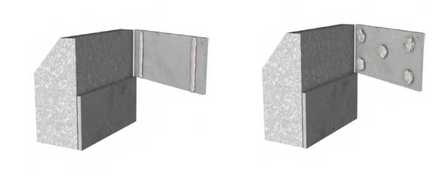

(2) DIRECT WALL INSTALLATION USING INVISIBLE FIXINGS

Tools and materials needed : -Bracket system -Spirit Level -Sealer -Screws and anchors -Tape measure -Cradle Caulking -Ladder/Scaffold tower/ Access platform -Angle grinder -Sandpaper -Paint Tray -Microfibre roller -Safety equipment

STEP BY STEP MANUAL INSTALLATION

-The wall should be levelled (+/-2 mm in 2 meters) -Sand the wall to remove any loose elements -The base has to be firm. Verify with a sharp tool -Define the way of installation according to the aesthetic wanted -Install bracket system -Begin the installation of the panels from the bottom up depending on design

3. WALL INSTALLATION USING VISIBLE MECHANICAL FIXINGS

Tools and materials needed This method is used when mechanical or chemical fixing is required

-Spirit Level -Drill /driver -Primer, sealer and Polyurethane / Epoxy adhesive -Screws, anchors and concrete or metal caps -Tape measure -Cradle Caulking Gun -Ladder /Scaffold tower/ Access platform -Tile Spacers -Angle grinder

-Sandpaper -Paint Tray -Microfibre roller -Safety equipment -Step By Step Manual Installation : -The wall should be levelled (+/-2 mm in 2 meters) -Sand the wall to remove any loose elements -Apply primer § The base has to be firm. Verify with a sharp tool

-Define the way of installation according to the aesthetic wanted -Begin the installation of the panels from the bottom up -Apply adhesive as per manufacturer’s recommendations -Install screws / bolts and metal or concrete caps in various colours -Seal the panels with Water Based Sealer, POLIFAN PU K14 or acrylic WAX