Livingconcrete Plain Concrete Tiles

Plain Concrete Tiles

PLAIN CONCRETE TILES

High-performance Plain Concrete Tiles are made to be stronger and lighter than conventional concrete tiles. They’re good for both indoor and outdoor installations and have a composition which allows for the manufacturing of thin, large format tiles that possess high strength and mechanical resistance at the same time.

Our tiles are made using a special combination of cement, sand and are specifically made with our leading blend of additives and UV stable pigments. The result is a concrete surface that is tough and functional.

We try to make it easy for you to get the support you need. That’s why we tailor our tiles to be suitable for variety of design applications, and they have a longer lifespan than other materials like slate or wood.

This type of option is perfect for any setting and a great choice for anyone who is looking at getting access to a cost-effective and long-lasting solution for their projects.

INFORMATION

BTX CONCRETE FEATURES

- Large format / ultra thin tiles with superior strength

- High mechanical resistance and UV stability

- Available in different textures and colours

- Suitable for floor and wall installation both indoor and outdoor

PRODUCTION

Made In London

CATEGORY

Concrete Tiles

MINIMUM ORDER

10m2

BRAND

Livingconcrete

MECHANICAL PROPERTIES

- Yield strength (modulus of rupture): 5-8 mpa

- Tensile strength (modulus of rupture): 2-5 mpa

- Compressive strength: 20-30 mpa

- Impact strength: 5-10 KJ/m2

- Thermal expansion coefficient: 20 x 10-6/°C

- Absorption: Low water permeability

- Dorry wear: 2.5 mm

COMPOSITION

- Cement

- Selected sand

- Specially designed additives and UV stable pigments. The BTX Ultra High Performance Concrete tiles stand out because of their versatility, durability and high hardness, making them suitable for all types of applications..

CLEANING AND MAINTENANCE

- Clean with neutral Detergent

- Use wax maintainers or self-polishing cleaners

STORAGE

- Keep in a dry, clean space in the original packaging

- Panels should be kept in a horizontal way

MATERIAL

- Hand-cast concrete - Brushed steel

INSTALLATION

Adhesive or bracket system

USE

- Internal

- External

DOWNLOAD

↓ Product Sheet

↓ Installation

COLOR VARIATIONS

Because of its cementitious composition the colour of GRC panels may have different textures and tones within the same panel and / or in comparison to other panels in the same batch. Our colour selection chart is for reference use only and the colours are as close as possible to the original colours.

VERIFICATION OF THE AESTHETIC APPEARANCE

Please check and ensure that you are happy with the delivered product and there are no apparent visible defects. If any issues are detected do not start the installation and contact supplier immediately. No claims will be accepted after tiles have been installed.

FINISHES

Unsealed or a choice or Matt, Satin or Gloss (we recommend sealing to limit staining).

TOLERANCES

- Thickness +/-5%

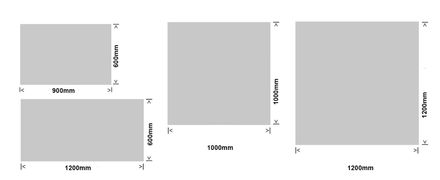

- Side straightness: +/-0.5% Orthogonality: +/-0.6% Planimetry: +/-0.5% Length and width +/-0.6%

CONSIDERATIONS BEFORE INSTALLING BTX TILES

-Keep packaged until installation -Do not force the tiles over uneven surfaces -Always store horizontally -Do not place loads on the tiles -Level the sub-floor correctly before starting the installation (+/- 2 mm in 3 m) -Place the tiles on the floor to choose your colour composition -Leave at least 5 mm for joints -BTX tiles are not rectified, they can have variations of 0.6%

APPLICATIONS

-BTX Ultra High Performance Concrete is lighter and stronger than conventional concrete -large format ultra thin pre-cast tiles-High mechanical resistance and UV stability -Easy made of natural materials -Great thermal conductivit-Available in many -Bespoke sizes and great alternative to poured polished concrete -Fast installation