The Splash Lab Radius Sensor Faucet Taps - TSL.882.BK

RADIUS SENSOR FAUCET TAPS - TSL.882.BK

RADIUS SENSOR FAUCET TAPS - TSL.882.BK

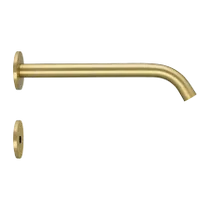

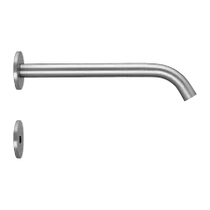

The TSL.882 Radius Sensor Faucet features a sleek wall mounted spout with accompanying sensor housing and is available in a range of finishes.

INFORMATION

AERATOR

Cascade

SENSOR TYPE

Infrared

WATER PRESSURE (DYNAMIC)

4.25 - 108psi

FEATURES

- Naturally pleasing and harmonious composition

- Minimalist wall-mounted spout

- mEnvironmentally friendly Titanium Ion Plating

- Easy installation

ALSO AVAILABLE

- 0.35gpm – refer to Spare Parts & Accessories

- 1.00gpm – refer to Spare Parts & Accessories

BODY MATERIAL

AISI 304 Stainless Steel PVD

WATER TEMPERATURE (MAX)

140 °F

COATING TYPE

PVD

FLOW RATES

0.5gpm

CABLE LENGTHS

- 31 ½ – Power supply connection

- 31 ½ – Solenoid valve connection

SENSOR TYPE

Infrared

SENSOR RANGE (MAX)

9 11/16"

COMFORT DELAY

2 sec

SECURITY TIME-OUT

30 sec

POWER SUPPLY

- Mains 110-230 Vac, 50-60Hz, 1.5A

- Battery 6 V CR-P2 Lithium battery 6 Vdc,

DOWNLOADS

↓ Data Sheet

↓ BIM

↓ Installation Manual

RESPONSE TIME (MAX)

0.3 – < 1 sec

WATER INGRESS

IP55

POWER CONSUMPTION

< 87% Active mode, 0.3W No load

OPERATING TEMPERATURE

32 - 122 °F

INSTALLATION REQUIREMENTS

WATER SUPPLY

Flush water supply lines thoroughly before installing the tap. Do not allow dirt, Teflon tape or metal particles to enter the tap. Shut off the water supply before installation. Gravity-fed systems may require a booster pump to achieve the optimal operating pressure.

FLOW RATES

The aerator supplied as standard has a flow rate of 0.50gpm. However, different flow rates may need to be achieved and The Splash Lab offer alternatives with flow rates of 0.35gpm and 1.0gpm respectively.

POWER SUPPLY

The TSL .882 IR Sensor Tap system is provided with a mains power supply (110-240Vac transformer) compatible for European and North American markets which requires wiring into a fused connection unit (FCU) or spur. To reduce installation costs the power supply can be wired into a junction box (not supplied) and then fed directly into a FCU or distribution board.

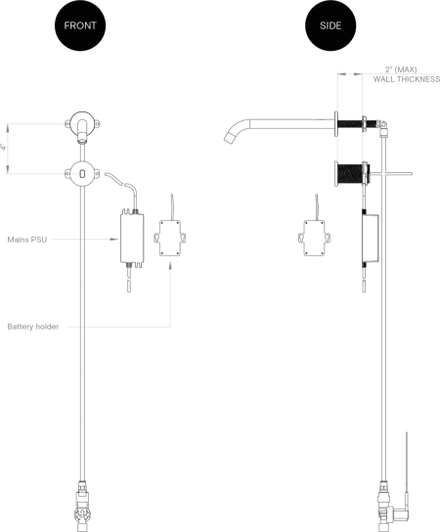

ACCESS REQUIREMENTS

It is critical all components which require fixing behind the wall are easily accessible at all times during installation and routine maintenance. Wall Cavity: a minimum cavity depth of 3 15/16” is recommended to ensure enough clearance for installing and commissioning tap components, connecting to mains water supply and safe installation of power supply.

MOUNTING LOCATION

+The maximum wall thickness the tap can be mounted to is 2” (incl. all finishes). The recommended distance from the center of the spout to the countertop of the washbasin is 8”. The distance between the center of the spout and sensor housing is 3 15/16” Ensure the holes and appropriate mounting points are created in accordance with the 1:1 drilling template shown on page 30. Taps should not be installed above highly polished surfaces to avoid reflection interference