Ecocooling Internal Evaporative Cooler

Internal Evaporative Cooler

INTERNAL EVAPORATIVE COOLER

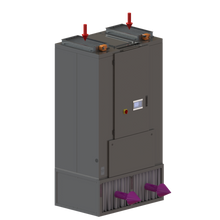

ECT10800

The ECT Internal range of evaporative coolers combine a ventilation system, evaporative cooling, recirculation, filtration and CREC® controls into a single box solution, this design significantly reduces installation costs

ECT units are not suitable for external use and are predominantly used in Data Centre and IT cooling installations.

FEATURES

CORE FEATURES

The ECT10800 internal evaporative cooler is shipped in two parts, the main cabinet and a separate filter plinth which is configurable.

ECOCOOLING CONTROL SYSTEM

The unit is controlled via a touchscreen user interface. Functionality includes logging of performance data and faults, altering of system parameters, a functional test routine and password protection.

EU4 FILTRATION

The airflow is subject to EU4 filtration both at the fresh air intake and at the point of supply.

DYNAMIC CONTROL

A consistent supply temperature is achieved year round by mixing cool air with warm recirculated air. Adjusting the speed of the supply fan keeps the exhaust temperature constant.

EFFICIENT FAN

A 630mm FE2owlet EC (Electronically Commutated) fan drives the airflow. Use of EC fans results in significantly quieter and more energy efficient operation than AC alternatives.

CONFIGURATION OPTIONS – PLINTHS

The cooler supplies air through a filter plinth. The front flow plinth is designed to deliver air through a deflection grille straight into the room. Alternative plinth panels and filters can be supplied which allow for side flow or connection of duct work.

SIMPLE SERVICING

Running a test routine to check the functionality of all components;.Cleaning the cooling module with fresh water;.Inspection and changing of filters if required. The internal evaporative cooler should be serviced quarterly.

Three stages are involved in a routine visit:

- Running a test routine to check the functionality of all components;

- Cleaning the cooling module with fresh water;

- Inspection and changing of filters if required.

All core components are situated at the front of the machine, just inside the cabinet doors and any of the electrical components can be changed in 30 minutes.

INFORMATION

TYPE

Internal Evaporative Cooler

PRODUCT CODE

ECT10800

WEIGHT

400kg

FRESH AIR INTAKE SIZE

- Height : 1100 mm

- Width : 320mm

RECIRCULATION AIR INTAKE SIZE (X2)

300 x 600mm

DOWNLOADS

↓ Data sheet

↓ Sales Leaflet

DIMENSIONS

- Height : 2494 m

- Width : 1304 m

- Depth : 960 m

DESIGN POWER USAGE (60% FAN SPEED):

- Cooling Mode and Ventilation Mode : 0.9kW

COOLING CAPACITY IN ADIABATIC MODE

35kW (ΔT of 8°C)

POWER SUPPLY

3~400V 50 Hz

DESIGN FLOW RATE

10,800m3/hr

COMMISSIONING AND SERVICING

EcoCooling offers a commissioning service which is completed after installation of the ECT10800 unit and inbuilt CREC® control system. It is recommended that the cooler is serviced every 3 months. Standard EcoCooling components are used, which are available ex-stock.

BENEFITS

The ECT10800 is part of EcoCooling’s internal evaporative cooler range, designed for use in data centres as an energy efficient alternative to refrigeration based systems. The ECT10800 can be configured with a humidification option which was developed for data centres in colder climates such as the Nordics, where very low humidity levels are problematic. The unit has a number of configuration options to accommodate varying installation constraints. The ECT unit is also available in a 5400m3/hr model for smaller IT loads and server rooms.

PERFORMANCE IN IT AND DATA CENTRE ENVIRONMENTS

The serviceable cooling load is dependent on the following factors: -Temperature rise between supply and exhaust (ΔT in the table below) -Volumetric air flow rate (10,800m3/hr)

| TEMP RISE, ΔT | 5°C | 7.5°C | 10°C | 12.5°C | 15°C |

|---|---|---|---|---|---|

| Serviceable cooling load (kW) | 18 | 27 | 36 | 45 | 52 |

ENERGY USAGE – INTERNAL EVAPORATIVE COOLER

The table below outlines the cost comparisons of the ECT10800 internal evaporative cooler with traditional DX (Direct Expansion) and CW (Chilled Water) air-conditi oning systems.

| TYPE OF COOLING SYSTEM | TYPICAL COP | EFFECT ON PUE | ENERGY USE (KW) | WATER USED IN EVAPORATION (M3 /YR) | ANNUAL RUNNING COST |

|---|---|---|---|---|---|

| ECT10800 | 39 | 0.026 | 0.9 | 40 | £828.40 |

| Direct Expansion CRAC | 2 | 0.5 | 17.5 | 0 | £15,338 |

| Chilled Water CRAC | 3 | 0.33 | 11.6 | 0 | £10,167 |

- System Design: 36kW cooling load. Electricity at 10p/kWhr. Water £1.00 m3. London location. 24/7 usage.

INSTALLATION

INSTALLATION REQUIREMENTS

-3 phase power supply -Fresh air intake -½” BSP mains water supply -32mm gravity drain pipe -Room sensor (temperature and relative humidity) -Pressure relief vent or extract fan